Although the basic mechanism of a Magic hose seems simple as you see it the actual axial extension and contraction (re-traction) mechanisms are very complicated as you also see its erratic and unexpected movement. It may be very difficult to control the change of its shape.

1) Basic concept (patented)

The outer fabric is generally not elastic and wrinkled or gathered like an accordion or a gathered skirt. This is the point and the key of the patent. The inner rubber tube naturally shows an circumferential (tangential) expansion (bulging) not axial expansion when water forcibly goes into (or "comes into" by seeing from the hose) the inner tube by the water pressure. When it reaches the outer fabric the circumferential (tangential) expansion is restricted by the non-elasticity of the fabric then extends axially by the continuous increase of water pressure. This axial extension stretches the wrinkles out to the axial direction or simply extends or stretches. This is the basic mechanism of the axial extension (and patented). This mechanism involves many factors so is very complicated. We can think of at least several factors factors shown below.

a) Surface conditions

The shapes and locations of the fabric wrinkles differ everywhere. So the friction between between the inner tube surface and and the outer fabric surface differ everywhere. The surface conditions (rough, smooth) of the inner tube and the outer fabric do matter very much. The fabric is, due to its woven nature, very water absorbent. The surface condition of the fabric may dramatically change after being wet,which is quite often observed as a hose handles water.

b) Water pressure

The water pressure in the inner tube differs everywhere in the inner tube. The X-Hose patent document mentions this as you see in later.

c) Stiffness

Stiffness (flexibility or elasticity)(*) of the rubber tube and even that of the fabric tube though not very elastic at all (but this is woven fabric) and the other less strict characteristics in term of mechanics like < (strong, weak; hard, soft> are supposed to be uniform in the same material but actually differ everywhere. The inner tube is usually two layered (the inner layer and the outer layer and usually different colors seen and the materials may differ) but one layer tube and three layer tube can be also seen in the products in the market. They are tried to have even thickness but this is ideal. They have thin parts and thick parts. The thinner parts expand first due to the pressure followed by the thicker parts if the pressure is the same all along the tube. (But the pressure differs by locations as mentioned above). Simply, the more stiff the more resistant to expand.

Therefore very complicated combinations are created only in the above considerations.

2) Rubber hysteresis

This is not often mentioned (not at all in the patent document) but might be considered as one of the factors of the retention ability of Magic Hoses as well as the friction mentioned above.

The X-hose patent document says

"

The water pressure within the garden hose is accomplished by introducing water under pressure into the inlet of the garden hose and restricting the flow of the water out of the outlet of the garden hose by use of a flow restrictor. The flow restrictor may be on/off valve 21 or a spray nozzle 25 capable of turning the water on and off. For example, the female inlet coupler 18 of the present invention 10 is secured to a water spigot 23 such as that found on the exterior wall of a home. The flow restrictor 21 is then secured to the outlet coupler 16 of the hose and placed in an off position so that water cannot pass. When the spigot 23 is opened the pressurized water enters the garden hose 10 and prevented from exiting the flow restrictor while in the off position, wherein the hose is expanded to its predefined length as limited by the outer tube member 12. For instance, a relatively normal pressure for municipal water is about 60 psi wherein the water within the hose is equalized to the same pressure. The flow restrictor 21 is preferable attached to a spray nozzle 25 or is part of the spray nozzle. The spray nozzle 25 can be a conventional water spray nozzle which varies the rate and spray pattern of water exiting from the nozzle but is capable of shutting off the exit of pressurized water. Many spray nozzles are L-shaped so as to be able to be comfortably gripped and used by an individual and have a pivoting on-off handle which operates an internal flow restrictor valve. A spray nozzle provides various amounts of restriction of water at the end of the garden hose depending on how large the opening in the nozzle is. The smaller the opening in the nozzle, the more the nozzle restricts the release of water at the end of the garden hose, and the higher the pressure and water volume inside the garden hose. The larger the opening in the nozzle, the less the nozzle restricts the release of water at the end of the garden hose, and the lower the pressure and water volume inside the garden hose. If the flow of water at the other end of the present invention was turned off and totally restricted, the psi inside the inner tube member would be the same as the pressure coming from the house, 60 psi. At this pressure, the inner tube member 14 and the outer tube member 12 in the present invention would expand to its maximum length. As the water at the end of the garden hose is released, the pressure becomes reduced inside the garden hose and the garden hose begins to contract. However, the present invention will remain fully expanded even when the pressure at the opposite end is reduced below the typical pressure of 60 psi coming from a house. In one example, the water pressure coming from the house was 60 psi and the water pressure exiting the nozzle at the other end of the water hose was 35 psi. This 35 psi of pressure inside the elastic inner tube member 14 was enough pressure to cause the inner tube member 14 to expand laterally and longitudinally until its lateral and longitudinal expansion became constrained by the non-elastic outer tube member 12 and expanded to the maximum length and width of the non-elastic outer tube member 12. In a preferred embodiment, the garden hose 10 expands from ten feet in length in its contracted condition to fifty feet in length in its expanded condition. Alternatively an on/off flow restrictor 21 can be used in combination with a spray nozzle 25 allowing the consumer a device to immediately turn off water to the spray nozzle.

"

5 bar = 72.5psi

4 bar = 58.0psi

3 bar = 43.5psi

"

This document the retention phenomenon but does not explain why ? Rubber has a relatively large hysteresis.

This may partly explain why ?

But this will be just a part of the many factors for keeping the hose expanded and extended at a relatively low pressure.

-----

(*) stiffness (flexibility or elasticity)

stiffness = Force / Displacement (extended portion), Unit: N/m

elasticity (Young module) = stress (pressure) / strain, Unit: N/m2

Flexibility (wiki)

"

The complementary concept is flexibility or pliability: the more flexible an object is, the less stiff it is.[2]

"

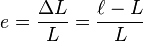

Strain (wiki)

"

is the engineering normal strain,

is the engineering normal strain,  is the original length of the fiber and

is the original length of the fiber and  is the final length of the fiber.

is the final length of the fiber."

So strain is just a ration and has no unit.

For more information, please contact

Asnet Dynamic Hoses - a division of

Asnet Components Ltd

Hong Kong (Wanchai Office / Sales)

23/F , On Hong Commercial Building,

145 Hennessy Road, Wanchai, Hong Kong

Tel: (852) 3578-5372

Fax: (852) 3582-3310

E-mail: sales-1@asnetcomp.com

www.asnetcomp.com