A typical (or good) Magic Hose has uses a very elastic latex (rubber) or TPE (Thermoplastic elastomer ) long tube of the inner diameter 6mm and outer diameter 10mm (therefore the thickness is 2mm). This is a thick wall cylinder tube. When a Magic Hose expands - in both radially or laterally and circumferentially or tangentially and axially or longitudinally - in three directions perpendicular each other in analysis. When water pressure applied inside (or to the inner wall) the diameter becomes large and the wall becomes thinner so it changes from a thick wall cylinder tube to a somehow thin-wall cylinder tube. Plus a Magic Hose extends (stretches) in the axial direction mostly by being forcibly restricted from expanding radially or laterally by the outer fabric (usually polyester) the mechanism seems highly complicated.

I have checked the mechanical formulas (equations) in some documents. They are not simple at all. Wiki 's <Cylinder Stress> explanation is too simple or shows only a very brief summary.

Wiki 's <Cylinder Stress> (25th July, 2015)

"

Relation to internal pressure

Thin-walled assumption

For the thin-walled assumption to be valid the vessel must have a wall thickness of no more than about one-tenth (often cited as one twentieth) of its radius. This allows for treating the wall as a surface, and subsequently using the Young–Laplace equation for estimating the hoop stress created by an internal pressure on a thin-walled cylindrical pressure vessel:

(for a cylinder)

(for a cylinder)

- P is the internal pressure

- t is the wall thickness

- r is the mean radius of the cylinder.

is the hoop stress.

is the hoop stress.

is developed and may be estimated in thin walled cylinders as:

is developed and may be estimated in thin walled cylinders as:The underline made by me. Without this condition (When the vessel has closed ends ) no axial stress and no radial stress are developed ? So only the hoop stress exists which make and keep the shape of cylinder. But atmospheric pressure exists around the cylinder. And the above first equation is also related with P (internal pressure).

Please note that these are some assumptions. The last equation of radial stress is <may be estimated> and just the half value of the opposite direction of the applied inner pressure regardless r and t. But no explanation is shown.

One explanation which I have found in

Strength of Materials and Structures

Chapter 9 Thin Cylinders and Shells

is also simple and somehow tricky.

"

.... the magnitude of the radial stress set up is so small in comparison with the hoop and longitudinal stresses that can be neglected. This is obviously an approximation since, in practice, it will vary from zero at the outside surface to a value equal to the internal pressure at the inside surface. ....>

"

Even

(for a cylinder)

(for a cylinder)

and

are relatively simple and we use a somehow tricky way to get as compared with thick walled cylinder due to some assumptions.

From: http://courses.washington.edu/me354a/Thin%20Walled%20Pressure%20vessels.pdf

PLD = 2σcLt or, σc (or σθ) = Pr/t is the circumferential stress in the wall

P = Pressure (blue arrow)

L = Length of the cylinder

σc (σθ) = Circumferential stress

A big assumption is PLD.

Pπr2 = σaπDt and thus the axial stress σa= Pr/2t

D = Diameter = 2r

A big assumption is Pπr2. Also is not easy to to be convinced that the pressure in this direction causes the stress in this direction. A more reasonable picture is

where σL is Longitudinal (Axial) stress

Please note that the direction of Longitudinal (Axial) stress, which may shrink the cylinder, not expand. A Magic Hose expands in this direction (Axial) when internal pressure is applied.

Now back to Wiki 's <Cylinder Stress> (25th July, 2015) and go on to Thick-walled vessels.

"

Thick-walled vessels

When the cylinder to be studied has a r/t ratio of less than 10 (often cited as 20) the thin-walled cylinder equations no longer hold since stresses vary significantly between inside and outside surfaces and shear stress through the cross section can no longer be neglected.

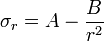

These stresses and strains can be calculated using the Lamé equations, a set of equations developed by French mathematician Gabriel Lamé.

- A and B are constants of integration, which may be discovered from the boundary conditions

- r is the radius at the point of interest (e.g., at the inside or outside walls)

if

then

then  and a solid cylinder cannot have an internal pressure so

and a solid cylinder cannot have an internal pressure so

"

Ri is the inner radius.

So to know more about these we must check <Lamé equations> at least. Also what are "boundary conditions" ?

I have found and checked some articles about thick walled cylinders which include <Lamé equations (or Lamé theory, etc)> and the conclusion is the same as shown above (wiki).

σr = A + B / r2

σt = A - B / r2

σt (Tangential stress) = σθ

or

σr = A + B / r2

σc = A - B / r2

σc (Circumferential stress) = σt = σθ

again where <A and B are constants of integration, which may be discovered from the boundary conditions.> and <A and B may be found by inspection of the boundary conditions.>

But the calculations somehow differ. And some calculations show apparent mistakes but the conclusions are the same, which is strange and interested me and made me think it worth spending time to check them carefully.

1) Mechanical principles - Thin walled vessels and thick walled cylinders

www.freestudy.co.uk/statics/complex/t1.pdf

I have found some mistakes in the calculation processes but reaches the same conclusion as

"

<Modified by me with full responsibility>

Remember the length of an arc length is radius x angle

Remember Force is stress x area

Remember for small angles the sin is the same as the angle in radians

Balancing the forces we have

(σR + δσR) (r + δr)δθ = σR r δ θ + 2σC δr sin [(1/2) δ θ ]

This resolves down to

(δσR/ δr) = (σC - σR)

However this should be

(δσR / δr) = (σC - σR) / r

as

(σR + δσR) (r + δr)δθ = σR r δ θ + 2σC δr sin [(1/2) δ θ ]

(σR+ δσR) (r + δr) = σr r + σC δr

σR r + σR δr + δσR r + δσR δr = σr r + σC δr

σR δr + δσR r = σC δr (δσRδr can be neglected as it is very small value)

σR δr = σC δr - δσR r

δσR r / δr = σC - σR

(δσR / δr) = (σC - σR) / r

Another mistake

(δσR / δr) = σC - σR (this is already a mistake)

In the limit this becomes (dσR / dr) = σC - σR ......... (4.1)

Without proof, it can be shown that the longitudinal stress and strain are the same at all radii.

(the proof of this is a long piece of work and would detract from the present studies if given here)

(my note: Or we can say here "assuming <the longitudinal stress and strain are the same at all radii.>")

The strain is given by

εL = 1/E {σL - υ(σC + σC) }

This is apparently a mistake and should be εL = 1/E {σL - υ(σR + σC) }

Since εL and σL are constant then it follows that (σR + σC) = constant.

The solution is simplified by making the constant 2A

σR + σC = 2A

σC= 2A - σR ......... (4.2)

Substitute (4.2) into (4.1) (dσr / dr) = σC - σR

(dσR / dr) = 2A - σR - σR = 2A - 2σR

Multiply all by r

r 2 (dσR / dr) - 2A r = 2 r σR

(my note: Please note

(4.1) should be (dσr / dr) = (σC - σR) / r

otherwise we cannot get

r 2 (dσR / dr) - 2A r = - 2 r σR )

Return to

r 2 (dσR / dr) - 2A r = 2 r σR

(this should be

r 2 (dσR / dr) - 2A r = - 2 r σR )

It can be shown that

d (r 2σR / dr) = r 2 (dσR / dr) + 2 r σR

d (r 2σR / dr) = 2A r

(I do not understand these two lines. Should be simply

d (r 2σR / dr) = r 2 (dσR / dr) so

r 2 (dσR / dr) + 2 r σR = 2A r )

r 2 (dσR / dr) + 2 r σR = 2A r

(my note: Integrating)

r 2σR =

(my note: where has 2 r σR gone ? )

where B (actually <-B>) is a constant of integration.

(Devising by r 2 )

σR = A - B/ r 2

σC = A + B/ r 2

Remember: a boundary condition is a known answer such as knowing what the pressure or stress is at a given radius.

2) http://www.roymech.co.uk/Useful_Tables/Mechanics/Cylinders.html

"

<Modified by me with full responsibility>

Initial Assumptions

The following relationships are assumed for

the strains ε1,ε2,

ε3 associated with the stress σ1,

σ2 and σ3.

υ = Poisson's ratio.

(E = Young's module)

Reference Notes on stress and strain

υ = Poisson's ratio.

(E = Young's module)

Reference Notes on stress and strain

Thick Cylinder basics

Consider a thick cylinder subject to internal pressure p1 and an external pressure p2. Under the

action of radial pressures on the surfaces the three principal stress will be σr compressive radial stress, σt tensile tangential stress and σa axial stress which is generally also tensile. The stress conditions occur throughout the section and vary primarily relative to the radius r. It is assumed that the axial stress σ a is constant along the length of the section...This condition generally applies away from the ends of the cylinder and away from discontinuities.

action of radial pressures on the surfaces the three principal stress will be σr compressive radial stress, σt tensile tangential stress and σa axial stress which is generally also tensile. The stress conditions occur throughout the section and vary primarily relative to the radius r. It is assumed that the axial stress σ a is constant along the length of the section...This condition generally applies away from the ends of the cylinder and away from discontinuities.

Consider a microscopically a small area under stress as shown. u is the radial displacement at radius r. The circumferential (Hoop) strain due to the internal pressure is

At the outer radius of the small section area (r + δr) the radius will increase to (u + δu). The

resulting radial strain as δr -> 0 is

Basis of equations

σr (radial) is equivalent to σ1

σt (tangential) is equivalent to σ2

σa (axial) is equivalent to σ3

derived equations

Eq. 1) ...... Eεa = σa - υσt - υσr

Eq. 2) ...... Eεt = Eu/r = σt - υσa - υσr

Eq. 3) ...... Eεr = Edu/dr = σr - υσt - υa

σr (radial) is equivalent to σ1

σt (tangential) is equivalent to σ2

σa (axial) is equivalent to σ3

derived equations

Eq. 1) ...... Eεa = σa - υσt - υσr

Eq. 2) ...... Eεt = Eu/r = σt - υσa - υσr

Eq. 3) ...... Eεr = Edu/dr = σr - υσt - υa

Edu/dr = σt - υσa - υσr + r [ dσt /dr - υ( dσa / dr ) - υ( dσr / dr ) ] = σr - υσt - υσa .. ( from 3

above )

Simplifying by collecting terms.

Eq. 4)........(σt - σr) (1 + υ) + r (dt /dr) - υr (dσa /dr) - υr (dσr /dr) = 0

Now from 1) above since εa is constant

Now from 1) above since εa is constant

Now considering the radial equilibrium of the element of the section. Forces based on unit length of

cylinder

(σr + δσr )(r + δr)δθ

- σr r δ θ - 2σt δ r sin [(1/2) δ θ ] = 0

(my note: The length of an arc is the <radius x angle in radian>. And Force is stress x area)

In the limit .sin [(1/2) δ θ ] - > [(1/2) δ θ ] and neglecting small products the equation reduces to.

(my note:

(σ r + δ σ r )(r + δ r)δθ - σ r r δ θ - 2σ t δ r sin [(1/2) δ θ ] = 0

(σ r + δ σ r )(r + δ r)δθ - σ r r δ θ - σ t δ r δ θ = 0

(σ r + δ σ r )(r + δ r) - σ r r - σ t δ r = 0

σ r r + σ r δ r + δ σ r r + δ σ r δ r- σ r r - σ t δ r = 0

σ r δ r + δ σ r r + δ σ r δ r - σ t δ r = 0

(my note: The length of an arc is the <radius x angle in radian>. And Force is stress x area)

In the limit .sin [(1/2) δ θ ] - > [(1/2) δ θ ] and neglecting small products the equation reduces to.

(my note:

(σ r + δ σ r )(r + δ r)δθ - σ r r δ θ - 2σ t δ r sin [(1/2) δ θ ] = 0

(σ r + δ σ r )(r + δ r)δθ - σ r r δ θ - σ t δ r δ θ = 0

(σ r + δ σ r )(r + δ r) - σ r r - σ t δ r = 0

σ r r + σ r δ r + δ σ r r + δ σ r δ r- σ r r - σ t δ r = 0

σ r δ r + δ σ r r + δ σ r δ r - σ t δ r = 0

only one small product is neglected, ie < δ σ r δ r> , then )

σr δ r + δσr r - σ t δ r = 0

σr δr + δσr r -σ t δr = 0... and as δr --> 0 then σr dr + dσr r - σt dr = 0 ... as δ .... (?) and this results in..

Now eliminating σt by substituting eq 6 into eq 5)

σr + r (dσr / dr) - σ r + r ( 1 - υ ) (dσt /dr) - υr (dσr /dr ) = 0

r ( 1 - υ )(dσr / dr) + r ( 1 - υ ) (dσt /dr) = 0

simplifying to

(dσr / dr) + (dσt / dr) = 0

Integration of this equation results in

σr + r (dσr / dr) - σ r + r ( 1 - υ ) (dσt /dr) - υr (dσr /dr ) = 0

r ( 1 - υ )(dσr / dr) + r ( 1 - υ ) (dσt /dr) = 0

simplifying to

(dσr / dr) + (dσt / dr) = 0

Integration of this equation results in

Eq.7) ....

σr + σ t = 2A (constant of integration.)

(my note: Not simply A. 2A is used to make the final equations look nice)

(my note: Not simply A. 2A is used to make the final equations look nice)

substituting this into equation 6 to eliminate σt

(my note: Eq.6) .... σr + r (dσr / dr) = σt )

σr + r (dσr / dr) = 2A - σr

Therefore

2A = 2σr + r (dσr / dr), which is equivalent to 2A = (1 /r ). d ([ r2. σ r ]/dr )

(my note: Again, where has 2σr gone ?)

therefore 2Ar = (d[r2.σr]/dr )

Which on integrating gives σr r2 = Ar2 + B

(my note: B is a constant of integration and originally <-B>)

with resulting

(my note: Eq.6) .... σr + r (dσr / dr) = σt )

σr + r (dσr / dr) = 2A - σr

Therefore

2A = 2σr + r (dσr / dr), which is equivalent to 2A = (1 /r ). d ([ r2. σ r ]/dr )

(my note: Again, where has 2σr gone ?)

therefore 2Ar = (d[r2.σr]/dr )

Which on integrating gives σr r2 = Ar2 + B

(my note: B is a constant of integration and originally <-B>)

with resulting

Eq 8) σr = A + B / r 2 and substituting this into Eq. 7)

Eq 9) σt = A - B / r 2

(my note: these two equation are opposite to those shown in wiki below.

Eq 9) σt = A - B / r 2

(my note: these two equation are opposite to those shown in wiki below.

)

)

General Equation for Thick Walled Cylinder The general equation for a thick walled cylinder subject to internal and external pressure can be easily obtained from eq)8 and eq) 9 as follows.

Consider a cylinder with and internal diameter d1, subject to an internal pressure p1. The external

diameter is d2 which is subject to an external pressure p2. The radial pressures at the surfaces are

the same as the applied pressures therefore

σ r = A + B / r 2

σ t = A - B / r 2

The radial pressures at the surfaces are the same as the applied pressures therefore

- p1 = A + B / r12

- p2 = A + B / r22

(my note:

- p1 - (- p2) = A + B / r 12 - ( A + B / r 22 )

p2 - p1 = A + B / r 12 - A - B / r 22

= B / r 12 - B / r 22

= (B r 22 - Br 12 ) / r 12 r 22

= B (r 22 - r 12 ) / r 12 r 22

then )

The resulting general equations are known as Lame's Equations and are shown as follows

If the external pressure is zero this reduces to

If the internal pressure is zero this reduces to

The longitudinal stress σa for a thick walled cylinder with closed ends is simply obtained from the equilibrium equation for a traverse section

-------

Besides the apparent mistakes one problem remains in the calculations in both articles.

my note: where has 2 r σR gone ?

my note: Again, where has 2σr gone ?

-----

One more pdf file

http://courses.washington.edu/me354a/Thick%20Walled%20Cylinders.pdf

Thick Walled Cylinders

I cannot copy some of the nice drawings. Please see the pdf file.

"

Consider a thick walled cylinder with open ends (underlined by me) as shown above. It is loaded by internal pressure Pi and external pressure Po as seen below. It has inner radius ri and outer radius ro.

Now consider and element at radius r and defined by an angle increment dθand a radial increment dr. By circular symmetry, the stresses σθand σrare functions of r only, not θand the shear stress on the element must be zero. For an element of unit thickness, radial force equilibrium gives:

(σr + dσr )(r+ dr)dθ = σrrdθ + σθ dθdr

Ignoring second order terms gives:

dσr / dr = (σr + σθ ) / r = 0 ......... (1)

(my note: This has a mistake as

(σr + dσr )(r+ dr)dθ = σrrdθ + σθ dθdr

σrrdθ + σrdrdθ + dσrrdθ + dσrdrdθ = σrrdθ + σθdθdr

dividing by dθ and re-arranging

σrdr + dσrr + dσrdrdθ = σθdr

Ignoring one second order term (which is dσrdrdθ) and re-arranging

σrdr + dσrr - σθdr = 0

dividing by dr x r

dσr / dr + (σr - σθ) / r = 0 ......... (1) )

Assuming that there are no body forces

Now consider strains in the element. By symmetry there is no θ displacement v (underlined by me) there is only a radial displacement u given by line aa’. Point c is displaced radially by (u + du) given by line cc’. As the original radial length of the element is dr (line ac), the radial strain is:

εr = (u + du) - u / dr = du / dr

Line ab has length rdθ and line a’b’ has length (r + u)dθ. The tangential strain is thus:

εθ = ( (r+ du)dθ - rdθ ) / rdθ = u / r

As the ends are open, σz = σ3 = 0 and we thus have plane stress conditions. From Hooke’slaw we get:

εr = du / dr = (1/E) (σr - υσθ)

εθ = u / r = (1/E) (σθ - σr)

(my note: this should be

εθ = u / r = (1/E) (σθ - υσr)

Solving for the stresses gives:

σr = E / (1 - υ 2 ) (du /dr + υ (u / r) )

σθ = E / (1 - υ 2 ) (u / r + (du /dr) )

(my note: the second one is a mistake and should be

σθ = E / (1 - υ 2 ) (u / r + υ (du /dr) )

Substituting into equation above yields:

(d2 u / dr2 ) + (1/r)(du /dr) - u / r2 = 0

Which has solution :

u = C1r + C2 / r

------

The calculation processes of the above two are largely omitted.

<Substituting into equation above yields: > means

Substituting the above two yields into the following equation we have (Equation ----- (1)) :

dσr / dr + (σr - σθ) / r = 0

------

One more and this time from a book Strength of Materials By Negi

Thick Walled Cylinders

Concept Review

14.1 Thick Walled Cylinders, Lame's equation"

r dσr / dr + 2σr = 2A

or

dr 2 σr/ dr + = 2rA

"

One more book

Strength of Materials and Structures

Chapter 10 Thick Cylinders

"

2A - σr - σr = r dσr / d

Multiplying through by r and rearranging

2σr r + r2 dσr / dr - 2Ar = 0

i.e. d (σr r2 - 2Ar2) / dr = constant = - B (say)

"

Still no explanation why 2σr can be deleted.

After further checking I have found one similar process in Chapter 4 <RINGS, DISCS AND CYLINDERS SUBJECTED TO ROTATION AND THERMAL GRADIENTS> in the same book Strength of Materials and Structures

"

4.2. Rotating solid disc

Now for equilibrium of the element radially

2σH δr sin δθ/2 + σr r δθ - (σr + δσr )(r + δr)δθ = ρr2ω2 δθδr

If δθ is small,

sin δθ/2 = δθ/2 radian

(my note

σH δr + σr r - (σr + δσr )(r + δr) = ρr2ω2 δr

σH δr + σr r - σr r - σr δr - δσr r - δσrδr= ρr2ω2 δr

σH δr - σr δr - δσr r = ρr2ω2 δr

σH - σr - δσr r / δr = ρr2ω2 )

Therefore in the limit, as δr --> 0 (and therefore δσr --> 0) the above equation reduces to

σH - σr - r dσr / dr = ρr2ω2

"

The underline drawn by me. <δr --> 0 (and therefore δσr --> 0)> means <1d/dn>.

But this does not explain why 2 r σR or 2 σr can be deleted.

-----------

I finally found an explanation and an answer to this question - a tricky application of the product rule of differentiation.

Cal Poly San Luis Obispo Mechanical Engineering

ME328 Introduction to Design

Cylinder Stresses

http://www.calpoly.edu/~jridgely/ME328/misc/cylinder.pdf

"

We eliminate σt from the two main equations above, put in the constant term C1, and get the following:

r dσr / dr + 2σr = 2C1

Then we multiply this thing by r to get

r2 dσr / dr + 2rσr = 2rC1

Now comes a one of those tricks which mathematicians seem to love. Notice that the stuff on the left of the equals sign in the equation above is equal to the derivative with respect to r of r2 σr. Then we can write the whole equation as

d ( r2 σr) / dr = 2rC1

This equation is easy to integrate with respect to r. We do so and get

r2 σr = r2 C1 + C2

(my note: The underlined is drawn by me.)

---------

The underlined part (the stuff on the left of the equals sign in the equation above is equal to the derivative with respect to r of r2 σr.) means

by using the following product rule

<r2 dσr / dr + 2rσr > is the derivative with respect to r of r2 σr.

d ( r2 σr) / dr = r2・dσr / dr + σr・dr2 / dr

= r2 dσr / dr + 2rσr

-------

After spending a lot of time on calculations now think about the basic things.

1) Differential equation

dσr / dr + (σr - σθ) / r = 0

This is one of the key equations. What does it mean ? Or what can we guess from this equation. Since it has <d/dr> is is a differential equation with regards to the variable radius <r>. Re-arranging it we get:

dσr / dr = (σθ - σr) / r

where

dσr / dr is the derivative of σr with regards <r>

σr = Radial stress

σθ = Tangential stress

r = Radius (neither the inner radius nor the outer radius of the wall of a tube but the inner radius of the representative infinitesimal element plane while <r + dr> is the outer radius of the element plane.

Therefore

the derivative of σr with regards to <r> equal to < Tangential stress - Radial stress > divided by the radius. Complicated isn't it ?

At least

a) The derivative of σr with regards to <r> is inversely proportional to the radius <r>. So the derivative of σr is smaller as the radius <r> is larger while the derivative of σr is larger as the radius <r> is smaller. But what does it mean ?

b) The derivative of σr with regards to <r> is proportional to < Tangential stress - Radial stress >. So the derivative of σr is smaller as <Tangential stress - Radial stress> is smaller while the derivative of σr is larger as <Tangential stress - Radial stress> is larger. But what does it mean ?

<Tangential stress> is larger than <Radial stress> or we can say < Tangential stress> is much larger than <Radial stress >.

2) Symmetry of cylinder tube

Circle Circumference, Circle Area, Sphere Area, Sphere Volume, Sphere Volume are symmetric about the center. Cylinder Area, Cylinder Volume are also symmetric about the axis. As shown above calculations we can omit or delete some calculations and simplify the equations of cylinder tubes by using these symmetry nature of tubes in terms of either stress or strain.

3) Longitudinal stress

We are concerned about Longitudinal stress as a Magic Hose expand in this direction. But remember

"

The longitudinal stress σa for a thick walled cylinder with closed ends is simply obtained from the equilibrium equation for a traverse section

"

Please note that the direction of the longitudinal stress σa , which is opposing the internal pressure. In this equation the outer pressure is neglected (considered as atmospheric pressure), but if it is considered ((considered as more than atmospheric pressure) the direction of the outer pressure is the same direction as the longitudinal stress σa at this area of the end of a cylinder. See below σL.

But when we see a thin walled cylinder the equation differs.

From; wiki and others

When the vessel has closed ends the internal pressure acts on them to develop a force along the axis of the cylinder. This is known as the axial stress and is usually less than the hoop stress.

where

t = wall thickness < r2 - r1 >.

Asnet Dynamic Hoses - a division of Asnet Components Ltd

Hong Kong (Wanchai Office / Sales)

23/F , On Hong Commercial Building,

145 Hennessy Road, Wanchai, Hong Kong

Tel: (852) 3578-5372

Fax: (852) 3582-3310

E-mail: sales-1@asnetcomp.com

www.asnetcomp.com

No comments:

Post a Comment